How we’re securing the flat glass of the future

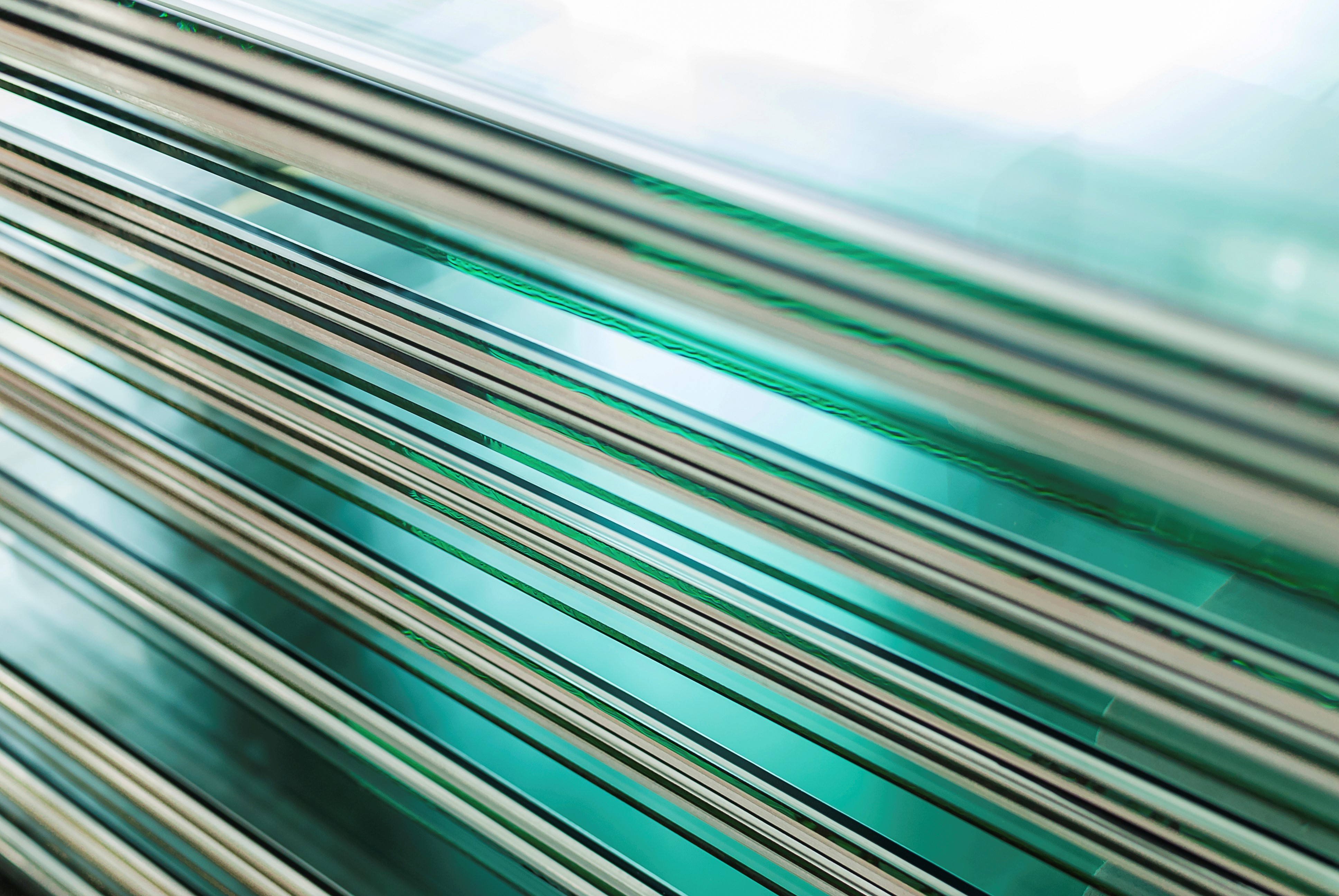

Flat glass plays a key role in our everyday lives, and is used in everything from windows to cars, solar panels, interior furnishing and monitors.

27 Aug 2024Recycling glass is not just good for the climate, it’s a necessity if we’re to have transparent flat glass available at all in the future.

How is flat glass manufactured?

Manufacturing flat glass from scratch is an energy-intensive process that affects both the environment and the climate. The glass consists of lime and soda, but above all of silicone dioxide, also known as silica, which is extracted from sand quarries. The material is melted and flows out to solidify on a flat surface. There are strict demands for the purity and quality of the raw materials, which means that there is a limited supply. And while demand for new flat glass is on the increase, the earth’s natural resources are decreasing. So what’s the real situation regarding circularity?

What happens to old flat glass?

Unfortunately, the majority of old flat glass currently ends up in landfill. In Sweden alone, we dispose of 35,000 tonnes of flat glass in landfill – every year. And even though glass does not contain any hazardous substances, it is non-biodegradable, which means it can take thousands of years to break down. The good news? With the right technology, flat glass is 100% recyclable – and we have the resources.

How does recycling take place?

Firstly, we work in close collaboration with property ownersto ensure that we collect flat glass efficiently. By offering training and advice, we can help companies to understand the importance of proper sorting and collection, which increases the amount of glass that can be recycled. It is once the flat glass has been collected that the hard part comes – carefully sorting the glass to achieve the correct quality. We therefore use optical sorting at our new flat glass recycling facility in Örebro. This is an advanced camera-based technology that can identify and separate glass by colour and quality, ensuring a high degree of purity in the recycled crushed glass. This enables us to deliver a recycled raw material to the flat glass manufacturer of a quality level that is as high as if it had been extracted from the earth. And the best part? Recycling flat glass saves 30% energy compared with producing new glass.